Membrane Bioreactor Using GPS-X Simulation Program. The membrane module calculations require user input values of membrane modue parameters that are typically available from the membrane module manufacturerer or vendor.

Standard Membrane Bioreactor Computations Mcgraw Hill Education Access Engineering

A complete design for an immersed membrane bioreactor iMBR can be.

. Other process parameters like bioreactor volume tank size hydraulic residence time HRT biomass loading FM ratio oxygen demand etc were calculated depending on. Very compact design Due to the membrane separation the active micro-organism population in the bioreactor can be maintained at a concentration 4-5 times higher than in conventional systems. The design of membrane depends upon the two main things analysis and the use purpose of water after treatment.

This Excel spreadsheet can be used to calculate the required volume and dimensions for the MBR aeration tank membrane module and preanoxic tank based on user. The overall AnMBR design efficiency is a careful accounting for how energy is used and produced during the reactor operation. Up to 10 cash back The design calculations were done based on the design parameters analysed from local textile wastewater and typical values of activated sludge kinetic coefficients.

Physical properties of the membrane and the result is that peak design flows should be no more than 15 to 2 times the average design flow. Conventional membrane bioreactor. The low membrane aeration flow-rate mode the standard operating mode with good sludge filterability enabled reduction of total aeration energy consumption by.

Obtained results from both hand calculations and the results of the program showed a good agreement. This report sets forth and details some of the energy calculations required for this assessment and a first order explanation of some of. The mechanism for mass transfer occurs via the process of convection as well as diffusion.

Microbial or other types in living cells get fed with the feed and they are able to freely circulate. The total surface area represents the total membrane surface area available for treatment in a membrane system. Number of membrane elements and membrane area are determined by the desired flux and the maximum membrane flow.

Membrane Bioreactor Design Calculations. The membrane bioreactor plant is dependent fully upon the ability of the filter to get good quality of water. Membrane operational time is calculated based on the cleaning intervals and duration.

The oilfield produced water entered into the reactor through the reactor inlet designated as In and passes through the immersed membrane. Ad Learn More About Filtration Membranes Components for Food Beverage Facilities. With Qoin m3day the equation with conversion factors becomes.

Performance Design Calculations There are a handful of calculations that can be used for design considerations and to judge the performance of a reverse osmosis RO or nanofiltration NF system. Membrane maximum flow is the highest value between the peak plant flow and the max average flow that considers the pauses for cleaning. Anaerobic fluidised membrane bioreactor.

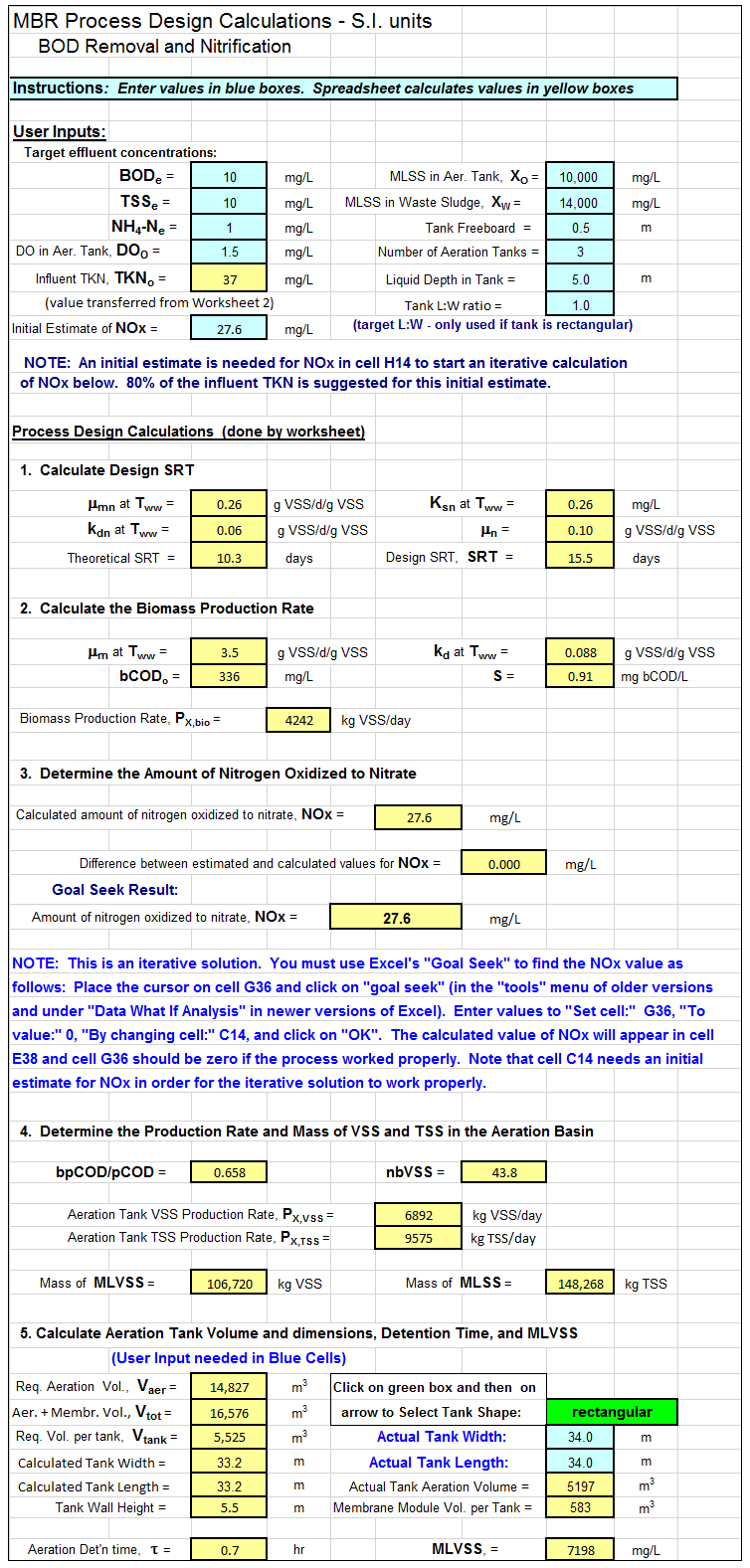

An example membrane bioreactor wastewater treatment calculations spreadsheet is partially shown in the image below. Overview of MBR Process Design Calculations. This results in bioreactor tank volumes of only 20-25 of the size of conventional systems.

Membrane area AM QoJ where Qois the wastewater flow rate in Lhr. The ability of this type of filter in filtration using membrane unit 02-005 μm pore size range would give high quality water. Ad Discover our broad selection of bioreactors fermenters for your biopharma process.

Development of MBR Design Equations Figure 1 shows a hypothetical schematic diagram of a Continuous Stirred-Tank Reactor imbedded with membrane submerged in the bioreactor for treatment of produced water. The membrane surface area requirement volume requirement and required scouring air flow rate for the membrane module can be calculated using membrane module properties typically available from membrane module manufacturers or vendors together with ng wastewater incomi information. Wastewater Engineering Treatment and Reuse 4th Ed New York NY 2003.

Example Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet. Case Study of Tikrit WWTP. If peak flows exceed that limit either additional membranes are needed simply to process the peak flow or equalization should be included in the overall design.

An example membrane bioreactor wastewater treatment calculations spreadsheet is partially shown in the image below. Using these membranemembrane module properties the required membrane area membrane module volume and scouring air flow rate can be calculated as follows. The total Permeated Flow over 24 hours divided by the total surface area expressed in gallons per minute per square foot.

The equalization is done by. A significant difference in the volume of secondary treatment was obtained from design calculations where the CAS without d e-nitrification system was 9244 m3. Scale seamlessly from 15mL to 2000L with Sarorius bioreactors.

On the membrane module being immersed in the aeration tank. Membrane bioreactor wastewater treatment calculations spreadsheet would you design application screensho a for everyone column how to in excel 2010. This Excel spreadsheet can be used to calculate the required volume and dimensions for the MBR aeration tank membrane module and preanoxic tank based on user.

Number of membrane elements and membrane area are determined by the desired flux and the maximum membrane flow. Net FluxTotal Permeate Flow Surface Area. COMMON TERMS AND DEFINITIONS.

Aerobic granulation membrane bioreactor. A clarifier being a space-consuming tank is not required. Example Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet.

The pressure gradient functions as an accelerating force. A m Q o J V m A m f Scouring Air Flow required A m. Membrane operational time is calculated based on the cleaning intervals and duration.

Membrane bioreactor design calculations If subtlety isnt your issue Select a little something with a bit more blingFrom words to jewels and also chains theres no Restrict into the 3D elements it is possible to connect to the nails so get Imaginative and Allow loose. Engineering Membrane Filtration Systems Since 1993. Membrane maximum flow is the highest value between the peak plant flow and the max average flow that considers the pauses for cleaning.

The design of the traditional membrane bioreactor is either internal or external. This bulletin outlines the various calculations that can be useful when designing or determining the performance of a system.

Input Screen For Mbr Module Part 1 Figure 7 Input Screen For Mbr Download Scientific Diagram

Amazon Com Spreadsheets For Mbr Wastewater Treatment Process Design Calculations Ebook Bengtson Harlan Books

Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At

Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At

Plutocalc Designer Handbook Mbr For Bod And Nh4 Removal

Amazon Com Spreadsheets For Mbr Wastewater Treatment Process Design Calculations Ebook Bengtson Harlan Books

0 comments

Post a Comment