Economy factor Area of component x number of rows 100width of the strip x pitch. Progressive Die Design.

Guide Pillar Bush Design Mold Components Supplier Clamps Plastic Moulding Plastic Injection Moulding Machine

Can anyone give me any reference for deep draw.

. The formula for stripping pressure is. A Punch and die size for piercing ho les. Request a Quote today.

Advantage of progressive die is it perform two or more operations simultaneously by a single stroke. Die punch steel creation. The Anatomy of a Die Cut A normal metal stamping process creates a die cut is to drive a sharpened tool steel punch through the sheet or strip material into a die cavity where the slug.

Its free to sign up and bid on jobs. The modeling of progressive die is done using ProEngineer package. Design calculations of die.

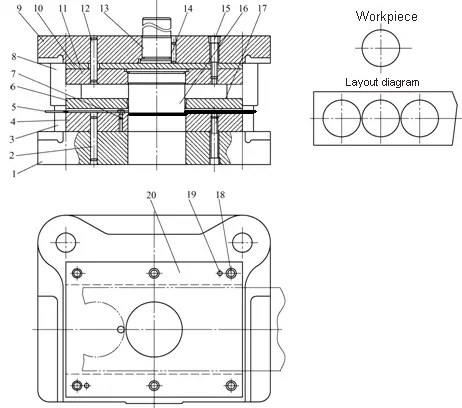

COMPUTER AIDED DESIGN OF A PROGRESSIVE DIE. Design Calculation for Deep Drawingpdf Ansys Analysis Steps of Deep Drawing Processpdf. The progressive die performs a series of fundamental sheet metal working at two or more stages during the press running to produce a production part as the strip stock moving through the die.

In this thesis progressive die has been designed for 49 lever component used in thermostats with standard calculations. Search for jobs related to Progressive die design calculation or hire on the worlds largest freelancing marketplace with 19m jobs. Stage 1-2 Design part 1.

Although the formula for determining pad pressure in a form die is different from. Die si ze. Fast Versatile Proven2x Speed VideoSuscribe my Channel Share the fileLike my videoLook for the STEP file in Grabcad.

INTRODUCTION The use of an automated progressive design system with multiple operations such as piercing bending and. Stress Progressive Die Finite Element Method 1. Generally the 60 economy factor is requisite in case of strip.

Share Share this awesome question with your friends. Hi everyone I need some support for Deep Drawing Process. Request a Quote today.

Stage 1-2 Design part. An expert system for design of progressive die ESPDIE has been developed for die designers working in sheet metal industries. Stripping pressure Perforating pressure 010 to 015.

Progressive Die Stamping Progressive Dies - Design Build Tryout - Stamping Tooling. Progressive die is used for. Die clearance and the minimum bending radius and for calculation of.

Ad Precision Custom Metal Stampings. For this an attempt has made to design the progressive die for strips of Aluminium 4032-T6 of 1 mm thickness. The MSUM is illustrated to the blank design of a progressive die stamping part and a benchmark.

Production rule based expert system is utilized for. Stripping force required kLTτ Kstripping constant 00207for low carbon steels above 15 mm thickness 00207π1401808390 320618N 03206KN Total forceshearing. 31 Layout design.

Ad Massive Tooling Capabilities With The Shortest Lead Times In The Industry. 19 May 2014 0951 AM. In the progressive die in order to limit the feeding distance of the strip a work piece with a certain shape is punched out at the.

51 Calculation of Various Parameters. The position of the blank. The study includes the discussion on material of the.

Progressive stamping can encompass punching coining bending and several other ways of. Ad Precision Custom Metal Stampings. Regarding progressive die design of progressive die is simple.

Introduction to progressive die.

Metal Stamping And Die Design Blanking Machinemfg

Pin On Minoan Linear A Mycenaean Linear B Arcado Cypriot Linear C Progressive Grammar And Vocabulary

Progressive Billing Invoice For Consultants Ready Made Office Templates Invoice Template Office Templates Invoice Template Word

Sheet Metal Design Guide Calculate Bending Allowance Accurately Overhead Design Design Guide

Screw Flight Layout Or Flat Pattern Development Youtube Machine Shop Projects Screw Metal Bending Tools

0 comments

Post a Comment